Production capabilities

Slitting Capabilities

Machine can slit films up to 200m/min and can slit from jumbo roll up to 1620mm width to multiple smaller widths.

Materials can be slit onto 54mm (2”) or 76mm (3”) internal diameter cores. The finished width can be determined by the customer and end application but we work to a standard width tolerance of ±1mm.

Various lengths of film can be slit depending on the thickness, we have experience of slitting very thin films from 12 micron total up to very thick films of >380 microns.

Films can be supplied with the adhesive on the inside or outside surface of the finished rolls and rolls with matched PET orientation can be supplied (with matching sequences) if specified at the time of order.

Pouch Conversion Capabilities

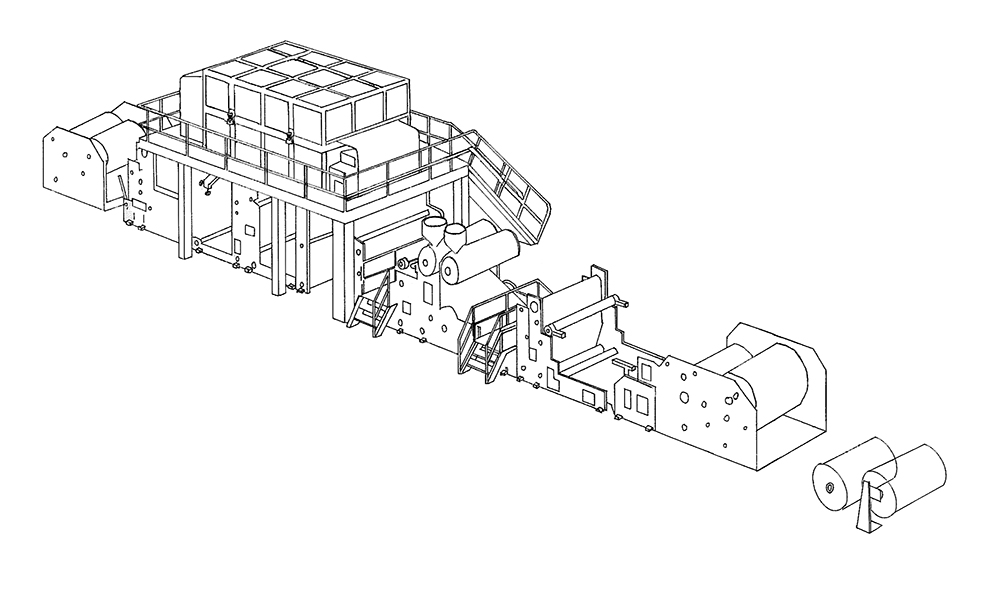

We have a dedicated pouch conversion line that can be used to create finished pouch/sheet products or can be hired on a contract basis for additional security.

The pouch conversion line is located in a separate, secure area for sensitive customer projects.

The conversion line has a maximum input width of 360mm, three unwind stations to allow the use of an internal core layer.

The line has a stripe lamination station with two lamination heads, a magnetic wrap die cutting station and a product collection belt.

Large Format Sheeting

We also operate large scale sheeters, designed for materials with medium to high rigidity. Our typical sheet size is 1450mm x 1000mm although other widths and lengths are possible.